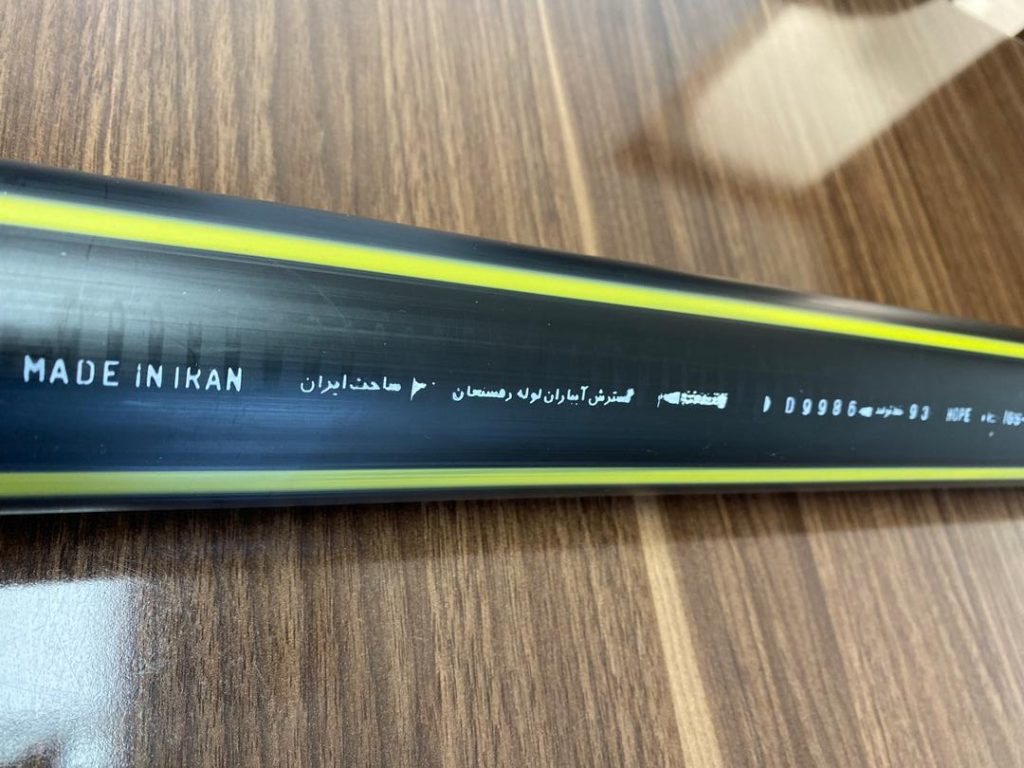

Gostaresh Abiyaran Luleh Rafsanjan Company,

being ranked number one among the companies producing polyethylene gas pipes by the National Iranian Gas Company and obtaining licenses to produce gas pipes from sizes 25 to 225, has been producing and selling its products to government agencies and private sector customers for many years.

In the production of polyethylene pipes for gas supply, quality materials and commercial grade PE100 are used. The production of these pipes requires sufficient precision and sensitivity.

Polyethylene gas pipes are produced according to EN 1555 and IGS-M-PL-014-01(2) standards. PE100 and self-colored materials are used in the production of these pipes. The polyethylene materials used in these pipes are uniform and self-colored and no additives or pigments are added to them, which results in the black color of these pipes.

Polyethylene gas pipes are very popular in gas supply projects due to their unique characteristics. Below, we will examine the most important advantages of these pipes:

1. Low weight and tensile properties

Gas polyethylene pipes are easily installed in curved paths due to their high elasticity. Their low weight makes transportation easier.

2. High strength

These pipes are resistant to UV radiation and have high strength against earthquake vibrations in buried conditions.

3. Long durability

The lifespan of gas polyethylene pipes is about 50 years, which makes them a reliable option for long-term projects.

4. Corrosion resistance

The acidic nature of gas polyethylene pipes makes them resistant to corrosion and abrasion. The high efficiency of these pipes is also one of their important advantages.

5. Cost-effective

With all their advantages, polyethylene gas pipes are the most cost-effective option for gas supply projects.

6. High resistance

These pipes are highly resistant to corrosive materials, alkaline and acidic fluids, and natural factors. They are also very resistant to impact and weldability.

7. No leakage and sedimentation

Polyethylene gas pipes do not leak or sediment under gas pressure.

8. Having a standard mark

These pipes are manufactured according to global standards and are therefore very popular in gas supply projects.

9. High chemical and physical resistance

The high chemical and physical resistance of these pipes prevents them from rotting or puncturing. They are also highly resistant to fire.

10. High-quality raw materials

High-quality raw materials are used to produce these pipes. Durable connections are another advantage.

11. Easy installation

Installation of polyethylene gas pipes is very easy, and their repairs are also low-cost and convenient.

Copied to clipboard